Digital Innovation in Productivity shortlist 2026

Six innovations have made the shortlist for the Digital Innovation in Productivity category, sponsored by Sage, at the Digital Construction Awards 2026.

This category recognises the use of digitalisation, digital methodologies and/or technologies to enhance the productivity of construction workers on a project or projects. Here are the six entries that made the shortlist.

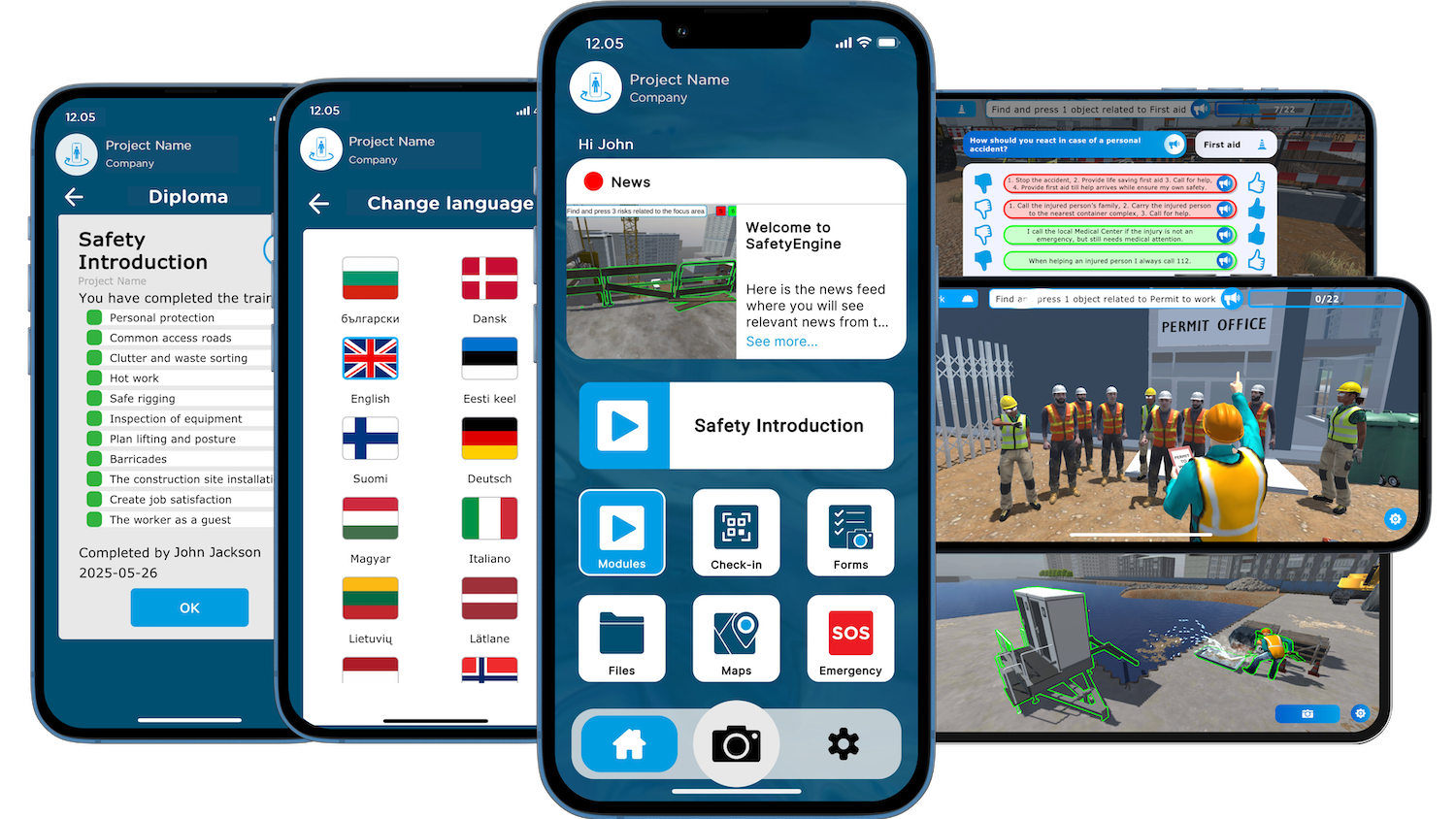

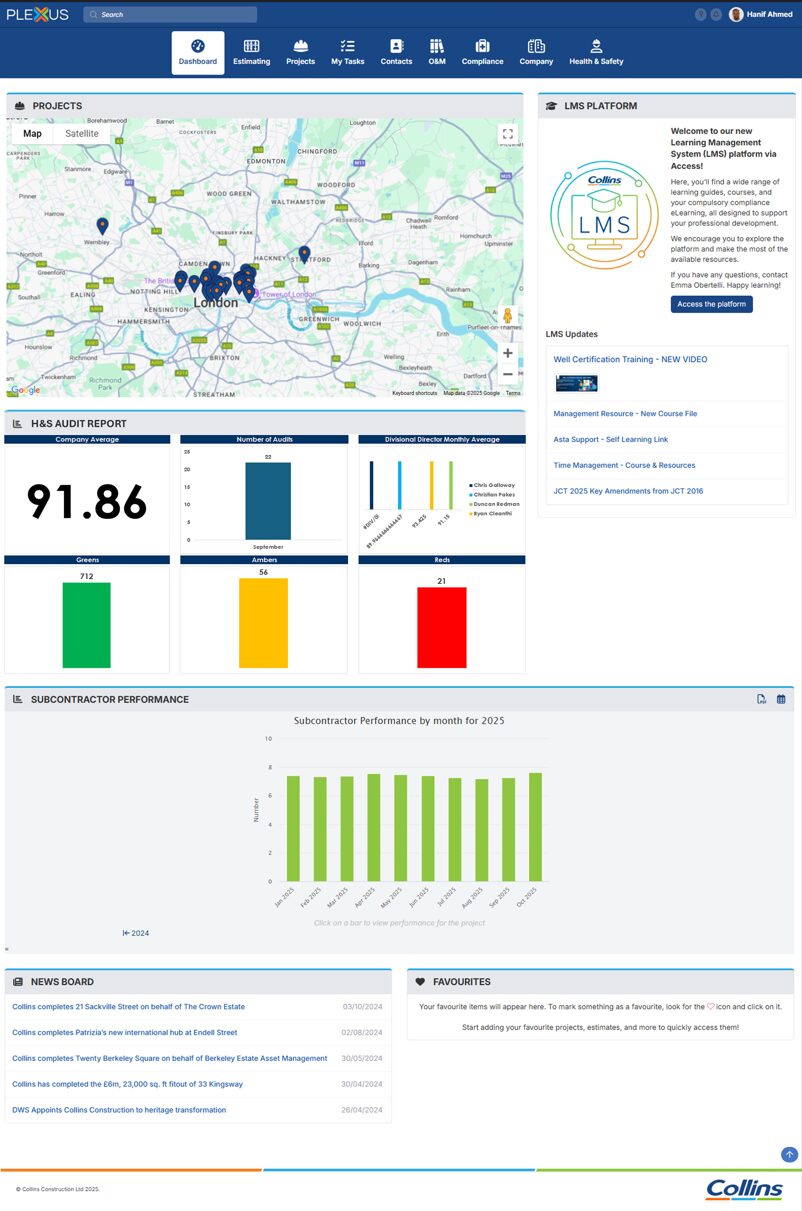

Collins Construction

By early 2025, Collins Construction’s site productivity was eroded by fragmented, paper‑based permits and inspections. Hot works, height and confined space permits lived in spreadsheets and email chains; health, safety, quality and environmental checks varied between sites and were often reviewed only after the event. Managers spent up to 20% of their time on administrative follow-ups instead of managing work, and critical activities were sometimes delayed due to missing permits or evidence.

Collins upgraded its in‑house ERP, Plexus, into a live control system for governance. Mobile‑first modules let operatives create, approve and sign permits on their phones, capturing methods, risks and controls at the point of work. Inspection checklists became configurable within Plexus, with automatic alerts, corrective‑action tracking and completion logging.

Fire safety routines were embedded in the daily diary, eliminating separate logbooks. Digital champions on each site co‑designed templates, delivered hands‑on training and drove adoption. The platform unified permits, inspections, drawings, contracts and tasks into a single source of truth, removing duplicate entry and disjointed apps.

The rollout across all UK projects, between January and October 2025, reduced approval times and eliminated start delays. Automated action assignment cut follow-up efforts, while live dashboards replaced spreadsheets.

Health and safety compliance was strengthened, with fire safety checks instantly auditable. The streamlined workflow saved time, lowered rework and delivered verified O&M packs at handover, boosting client satisfaction and reinforcing a culture where compliance is a productivity enabler rather than a burden.

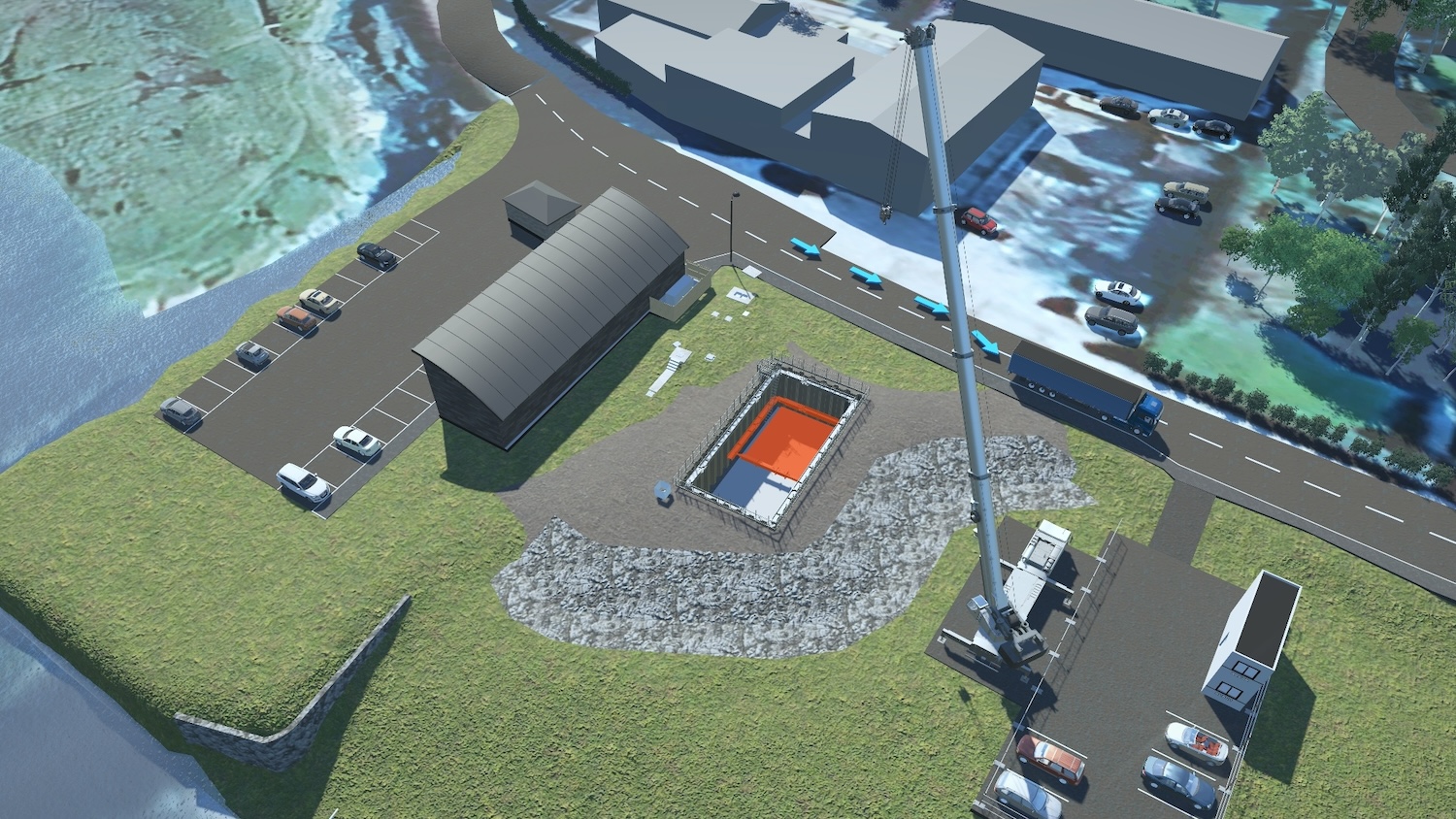

Dearne Reach integrated constructed wetland | Mott MacDonald Bentley/Yorkshire Water

The Dearne Reach wetland – a 4.3ha integrated constructed wetland – had to be built by July 2025 despite a wet, cold winter. Traditional earthworks planning risked oversized machinery, excess cut and fill, long set‑out times, safety hazards and missed regulatory deadlines for ammonia reduction along the River Dearne.

Mott MacDonald Bentley uploaded the design model into the Smart Construction platform that uses AI to size and schedule intelligent plant. The system generated an optimal earth shifting plan, selecting five D6 dozers, two 36‑tonne excavators and four 21‑tonne excavators.

Point cloud surveys fed a dashboard that automatically calculated cut/fill volumes, monitored real‑time progress and compared actual grades to design. Engineers uploaded the model, watched the dashboard, and only intervened at the end of the day, eliminating manual setting‑out, banksmen and constant plant‑engineer interaction. The AI‑driven workflow achieved a perfect cut‑fill balance, moving more than 63,000 cu m of earth without the need to transport any of the materials offsite.

Zero overcutting and no soil haulage eliminated waste and reduced carbon emissions. The intelligent‑plant approach trimmed the programme by three weeks, saving roughly £350,000, and delivered the wetland on schedule despite adverse weather.

Safety improved markedly by limiting people‑plant contact, and post‑project data revealed more efficient excavation patterns (shorter, deeper drives, optimal blade angles) that will inform future Smart Construction simulations.

Digital productivity and change management across live projects | Shape Construction

A fragmented approach to daily progress, issue tracking and change notification produces unreliable records, delays visibility of blockers (such as material delays, access constraints or weather impacts), and forces a reactive response that erodes productivity and commercial certainty.

Shape Construction’s platform is the answer to these challenges. It was deployed at the Lewisham Gateway project (among other projects) as a fully integrated, field‑first performance‑management system. Mobile‑enabled modules – Shift Manager for daily reporting, Weekly Work Planner for schedule alignment, Issue Tracker for logging and escalation, and a control room for change‑signal tracking – mirrored existing site rhythms without adding complexity.

Records were automatically structured in the Microsoft Dataverse and instantly visible to commercial and planning teams. The change‑tracking workflow linked every disruption to evidence (photos, conversations and daily logs), enabling immediate triage and entitlement preservation. No specialist training was required: teams simply logged the day’s work, raised issues and communicated through a single channel.

Across all 2025 deployments, issue resolution time was reduced by 77% (from three days to under one), and weekly plan adherence rose by 15%, as measured through the platform’s percent plan complete data.

Lewisham Gateway alone generated more than 14,000 structured progress records, creating a commercial‑grade audit trail that saved hours of admin each week. Documented change events secured extensions and cost recoveries – for example, BySteel obtained a two-and-a-half month time extension backed by detailed issue reports.

Overall, the platform delivered a closed‑loop productivity system, giving site teams real‑time visibility, commercial teams provable entitlement, and project leaders the confidence to steer delivery effectively.

Hinkley Point C workpacks: a nuclear boost for productivity | BYLOR JV (Bouygues Travaux Publics and Laing O’Rourke)

The heat sink pump house at Hinkley Point C required more than 4,000 concrete pours on each unit and the world’s largest seawater‑pumping system. Its complex geometry, limited access and the need for strict quality and traceability made traditional material‑tracking methods impractical. Downtime, material loss and poor stock visibility challenged productivity, safety and sustainability.

BYLOR built an in‑house ‘workpacks’ system using Python scripts to combine geometric data, embedded‑item lists, consumable inventories and orientation images into a single, standardised package for each element.

The workpacks were hosted in Trimble Connect and accessed on tablets. A dedicated onsite facility produced lineside stillages that bundled the exact materials and consumables required for each workpack, delivering them just-in-time to the crew. The semi‑automated workflow replaced manual paperwork, reduced human error and integrated seamlessly with the existing digital model viewer used onsite.

The approach cut lifting operations from six lifts per wall to one. Recycling of materials and having the facility to make good of consumables resulted in £30,000 cost savings within six months on rebar consumables alone.

The system also improved logistics hugely by reducing incoming trailers, ultimately improving trailer management and carbon footprint, and reducing trailer movement on average from six trailers to one trailer.

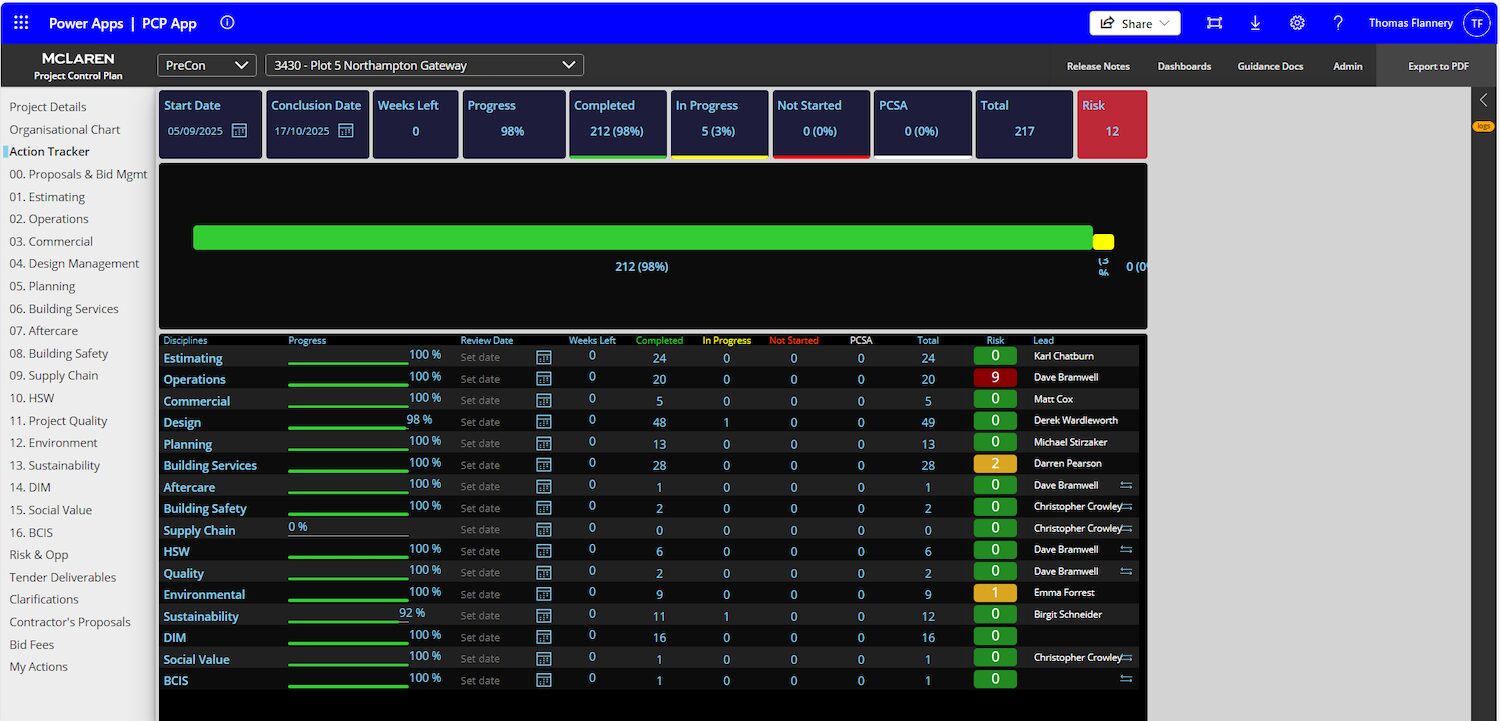

Project Control Plan | McLaren Construction

Against a backdrop of chronic skill shortages, tighter regulations and a tough macro-economic climate, McLaren needed a way to integrate, standardise and accelerate delivery while remaining compliant with new building safety legislation, identifying required skills early and creating a golden thread of information from tender to handover.

Thus, McLaren launched a digital operating model centred on a bespoke project control plan (PCP) application. Built on a Microsoft Fabric data lakehouse and linked to core platforms such as Dalux and Asite, the PCP provides a single source of truth for activity schedules, risk registers, competency overviews and reporting metrics.

A dedicated support team delivered training, e‑learning and weekly drop‑ins to embed the tool, while a phased rollout accommodated varying digitisation maturity across functions.

The PCP standardises work-winning and project delivery, cutting administrative effort for monthly reporting by up to a third and reducing uncontrolled documents by 10%. Cloud‑based workflows lower internal email traffic by more than 50 %, improve information accessibility and enable earlier cost, quality and programme risk mitigation, ultimately driving more certain, efficient and profitable projects.

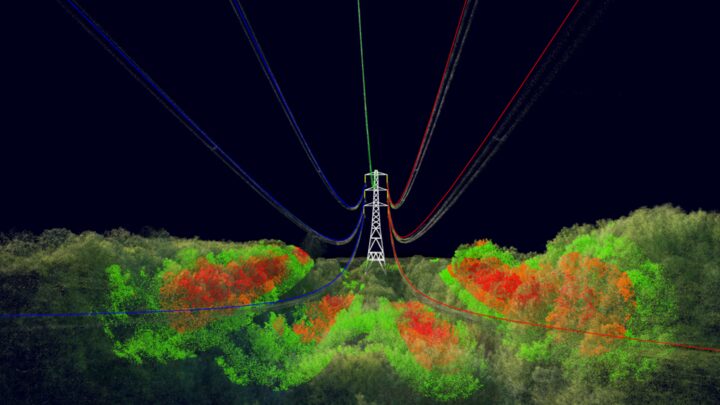

Sensat deployed advanced helicopter-mounted LiDAR survey for National Grid

National Grid needed a more accurate, efficient way to manage vegetation encroachment along its electricity transmission network. Traditional ground surveys were time‑consuming, prone to error and often required repeated site visits, leading to higher operational costs, increased network disruption and limited visibility for cross-team coordination.

National Grid partnered with Sensat to deploy helicopter‑mounted LiDAR surveys, producing high‑resolution, colourised 3D visualisations of the entire network. Sensat’s visualisation tools modelled assets under varied operating conditions and automated distance analyses, creating a data‑driven single source of truth. A dedicated digital workflow streamlined data interpretation, allowing rapid identification of vegetation hotspots and prioritisation of clearance work without extensive manual analysis.

The data-driven approach delivered significant efficiency gains, saving time, reducing costs and improving safety through more informed, risk-based decision-making. The ability to visualise and analyse assets in a 3D environment enabled the team to target only those areas requiring attention, reducing unnecessary site visits and optimising resource allocation.

Beyond the immediate operational benefits, this digital methodology improved cross-team collaboration and long-term planning. The shared visual model provided a single source of truth for all stakeholders, supporting better communication, transparency and alignment across teams.

Celebrate with the best

The winner will be revealed at the gala dinner at the London Marriott Grosvenor Square on 18 March. You can join the shortlisted entrants by booking your seats at the awards.

The Digital Construction Awards are organised by Digital Construction Week, DC+, Construction Management and the Chartered Institute of Building. Bluebeam, nima and Sage are among the sponsors.

To find out more about the awards, head to digitalconstructionawards.co.uk.

To become an awards sponsor, email Karolina Orecchini.

Keep up to date with DC+: sign up for the midweek newsletter.