Why information management is the next frontier for health and safety

If information management can reduce cost and time risk, why not apply the same discipline to health and safety? Lawrence Chapman at Sizewell C (and previously HS2) answers the question.

Digital engineering has transformed the way the UK builds. From 3D modelling to asset data handover, project teams are now well-versed in the language of ISO 19650. But when it comes to health and safety, the industry is still lagging.

Risk assessments remain locked in pdfs, temporary works registers in spreadsheets, interface logs hidden in emails, and incident reports trapped in proprietary systems. The result? Safety information too often remains siloed, disconnected from design, programme and asset data.

The missing link in digital construction

The publication of ISO 19650-6 has shed light on this gap. For the first time, there is an international standard dedicated to health and safety information management.

It sets out how hazards, risk assessments and mitigation measures should be specified, exchanged and controlled within a CDE. In short: safety data should be treated with the same rigour as drawings, models and asset registers.

This shift aligns neatly with the Construction (Design and Management) Regulations 2015 (CDM), which already place duties on clients, designers and contractors to eliminate or control risk. Digital processes offer a way to demonstrate that those duties are being discharged – with a clear audit trail of who identified which risks, when and how they were addressed.

“To strengthen learning outcomes, information managers should be embedded in post-incident investigations. Their role is to assess whether any failures in information management contributed to the event.”

Towards predictive safety

So what changes if we fully integrate health and safety data into the CDE?

- RAMS as live data – risk assessments and method statements (RAMS) are linked directly to specific activities in the programme.

- Temporary works in the model – approvals and designs are federated within the CDE, traceable to installation activities.

- Interface registers visible to all – enabling clashes and access conflicts to be resolved in advance.

- Incident and near-miss data structured – tagged to assets, zones or contractors, supporting trend analysis.

- Digital rehearsal safety briefings – 3D/4D models can be used to ‘walk the job’ virtually, showing crews where exclusion zones are, how access routes change, or where lifting operations overlap before they step on site.

The result is a shift from reactive investigation to predictive safety. Instead of waiting for incidents to happen, projects can spot trends, learn from near misses and intervene earlier.

Breaking down the benefits

Integrating safety data into the CDE delivers:

- a single source of truth – avoiding outdated or conflicting safety information;

- traceability – linking permits, approvals and incidents directly to the relevant assets and activities;

- faster feedback loops – lessons from incidents drive immediate updates to RAMS or designs;

- predictive analytics – structured data enables risk hotspots to be identified across projects and supply chains; and

- regulatory assurance – demonstrating compliance with CDM 2015 and ISO 19650.

As one industry practitioner puts it: “We already manage programme and cost risk through integrated systems: safety deserves the same treatment.”

RIDDOR reporting through the PIM

Another area where digital integration can deliver major benefits is RIDDOR (Reporting of Injuries, Diseases and Dangerous Occurrences Regulations 2013) compliance.

Today, many RIDDOR reports are created manually, relying on site teams to complete forms, collate evidence and send them to the Health & Safety Executive (HSE). This process is slow, prone to error and often disconnected from project data.

“Embedding RIDDOR reporting into the PIM not only improves compliance, but also turns statutory reporting into a valuable dataset for predictive safety management.”

By embedding RIDDOR reporting into the project information model (PIM):

- incidents are logged once, at source – photos, witness statements and location data are attached directly to the information container;

- data is automatically populated – incident records already structured in the PIM can populate much of the RIDDOR form automatically, reducing admin and improving accuracy;

- traceability is improved – each RIDDOR case is linked to the relevant work package, asset contractor and RAMS, enabling root-cause analysis;

- analytics and benchmarking is enabled – consistent digital records allow projects and clients to track trends across multiple sites, contractors and years; and

- information gaps can be identified – by connecting RIDDOR reports back into the PIM, it becomes possible to spot where missing or poor-quality information was itself a contributing factor to the incident. For example, outdated RAMS, unapproved temporary works or missing interface data may emerge as root causes, highlighting weaknesses in the information flow as well as site practice.

This integration not only improves compliance, it also turns statutory reporting into a valuable dataset for predictive safety management. Instead of being a paper exercise, RIDDOR data becomes part of the project’s intelligence system.

Information manager’s role in investigations

To strengthen learning outcomes, information managers should be embedded in post-incident investigations. Their role is to assess whether any failures in information management contributed to the event – for example, missing or outdated RAMS, failures in not progressively updating models in a timely manner, unapproved temporary works, or incomplete interface data.

By analysing the information flow alongside operational and technical causes, information managers can help identify systemic weaknesses that traditional health and safety investigations might overlook. This ensures that lessons learned are not only about site practice, but also how information is created, updated, shared, approved and used within the project environment.

“Not everything needs to be modelled in 3D. What matters is that information is coordinated, connected and managed through the PIM.”

A cultural shift

The technology to do this already exists – the challenge is cultural. Health and safety processes are still wedded to static documents. To realise the potential of ISO 19650-6, the industry needs to shift towards structured, federated data.

And crucially, not everything needs to be modelled in 3D. What matters is that information is coordinated, connected and managed through the PIM. Some safety information is best expressed graphically, for example, using models for digital rehearsal safety briefings, where site teams can visualise work sequences, exclusion zones or traffic flows before stepping on site. Other data – such as RAMS approvals, temporary works sign-offs or incident reports – will remain textual or tabular.

The value comes when all of it, graphical and non-graphical alike, is federated and referenced consistently. This ensures decision-makers and operatives see a complete, connected picture, not fragments scattered across multiple systems.

Clients have a key role to play. By embedding health and safety integration into Exchange Information Requirements (EIRs), they can set expectations for the entire supply chain. Contractors, in turn, must move beyond pdfs and spreadsheets towards live, connected information containers.

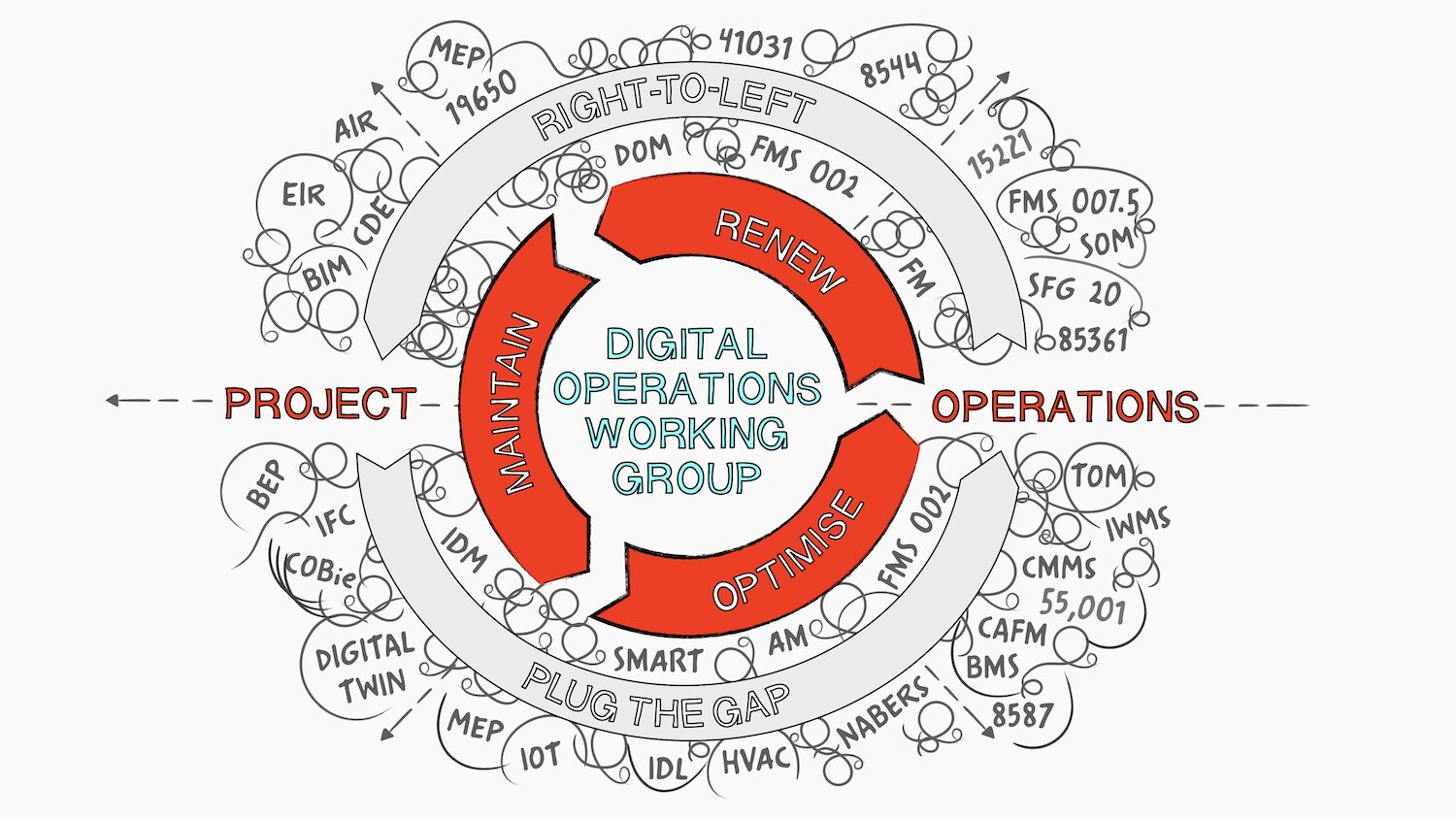

Driving change

The BIM for Health and Safety Working Group, supported by nima, has long advocated for this integration. Its guidance shows how hazards can be visualised in models where appropriate, and just as importantly, how non-graphical data can be connected to those models to improve coordination and communication.

The group’s work complements ISO 19650-6 by providing practical methods for applying digital processes to improve safety outcomes.

Information management has always been about reducing risk. Extending its discipline into health and safety – guided by ISO 19650-6, aligned with CDM 2015, and supported by the BIM for Health and Safety Working Group – represents the next frontier.

Done well, it turns safety data from static compliance into live intelligence. That not only saves lives, but also delivers more predictable, efficient and transparent projects. For projects under pressure to deliver safely, efficiently and sustainably, this is an opportunity the industry cannot afford to ignore.

The opinions expressed are the author’s own and do not necessarily reflect the views of his employer.

Keep up to date with DC+: sign up for the midweek newsletter.