It’s time to embrace 3D printing

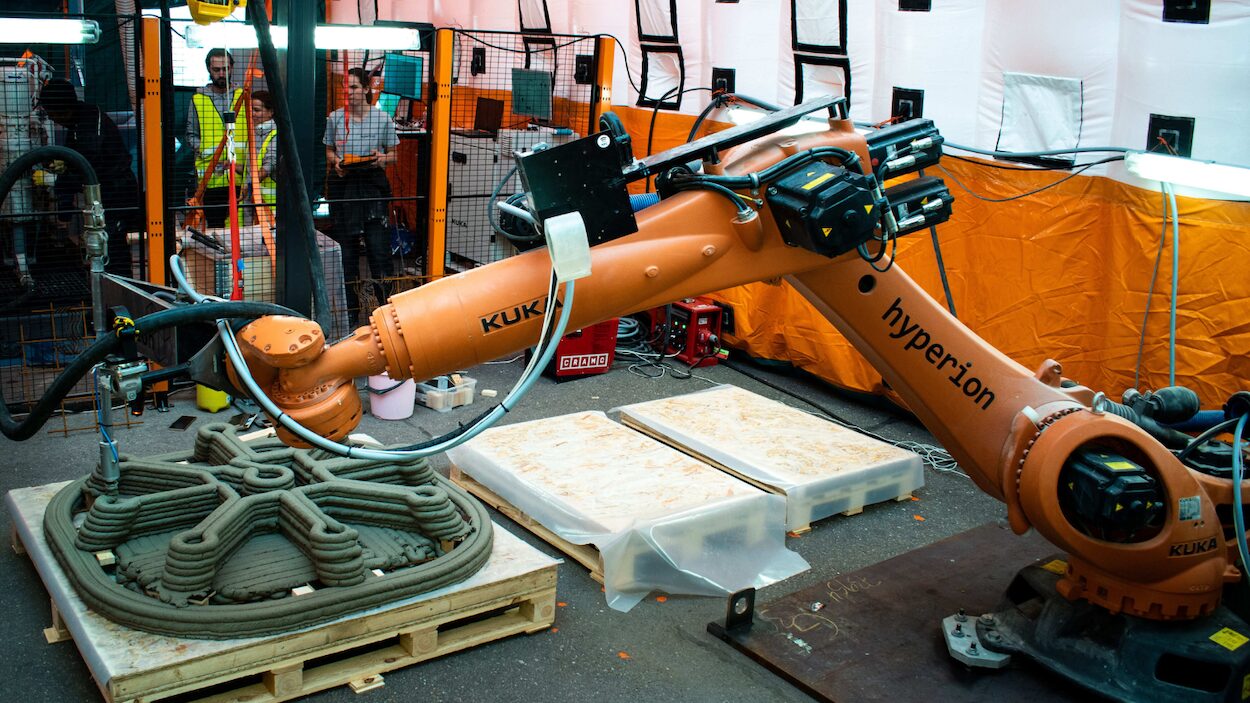

What’s stopping you adopting 3D printing at scale? Is it concerns about the structural rigidity, that it’s only for bespoke projects or the cost? They’re all myths that Fernando De los Rios of Hyperion Robotics is keen to dispel.

We are at a crossroads. Infrastructure demands are soaring, sustainability targets tightening and project timelines more compressed. Yet despite proven technological solutions that deliver significant cost, time and carbon savings, adoption of advanced construction methods remains slow.

Additive manufacturing, or 3D printing, falls into this category. Nothing is stopping 3D printing from scaling across utilities, transport, data centres and energy infrastructure.

Indeed, the technology is ready, but several misconceptions are holding the industry back.

The most pervasive myth I encounter is the belief that 3D-printed structures are inherently weak because they’re built layer by layer – like a cake that might easily crumble. In fact, the opposite is true. When concrete is 3D printed, the layers fuse together to create a homogeneous structure. Through extensive third-party testing, we’ve consistently demonstrated that our 3D printed structures are actually stronger than conventional concrete – in some cases, by up to 10 times.

“The most pervasive myth I encounter is the belief that 3D-printed structures are inherently weak because they’re built layer by layer – like a cake that might easily crumble. In fact, the opposite is true.”

Another misconception is that 3D printing is a prototyping tool suitable for one-off, highly bespoke elements. This view stems from early applications that failed to find the right balance between customisation and standardisation. At Hyperion, we’ve developed what I call ‘standardised customisation’ – parametric digital models that allow us to create variations of core products such as foundations. Put simply, this allows us to serve projects in need of hundreds or thousands of units, each tailored to specific site conditions without the complexity of starting from scratch every time.

Too costly?

Perhaps the most significant barrier is the perception around cost. Many assume that complex machinery invariably leads to expensive products. However, this assumption focuses on unit price, not total project cost. When you factor in material savings of up to 75%, reduced transportation costs, faster installation times and elimination of complex formwork, overall project savings typically range from 20% to 50%. The key is understanding where 3D printing delivers maximum value – applications where we can optimise material placement, simplify complex geometries and reduce labour.

Integration concerns also create hesitation. Construction companies worry about disrupting established workflows, but we’ve addressed this by operating like a traditional precast manufacturer. Contractors simply place purchase orders, receive quotes and install delivered elements using familiar processes. This approach removes the risk and complexity of adopting new on-site equipment and delivers the benefits of 3D printing technology.

Sector-specific opportunities

Different industries present unique opportunities for 3D printing where its advantages become particularly compelling.

Utilities, for example, is characterised by tight timelines and the need for customised solutions, which creates perfect conditions for our technology. Each water treatment plant or substation requires different specifications to fit specific site conditions – something that would require expensive bespoke moulds using conventional methods. With 3D printing, we can adjust designs parametrically using software, delivering exactly what’s needed within compressed timeframes.

Our collaboration with the National Grid perfectly illustrates this potential. We are working with the organisation on a UK-first trial to manufacture, install and test low-carbon, 3D-printed substation foundations. Despite using 70% less material, structural testing has proven our foundations are four times stronger than traditional construction methods. If rolled out across National Grid substations, this could save up to 705 tonnes of concrete and 323 tonnes of CO₂, all while delivering £1.7m in consumer savings over a decade.

The transport sector also offers enormous scale opportunities. Rail and road projects often require thousands of foundations, each with slight variations due to different soil conditions or infrastructure requirements. This is where a mobile micro-factory concept becomes compelling – these are production facilities that can move along project routes and manufacture hundreds of units at each location. This offers production efficiency while avoiding transport costs and emissions.

“Perhaps the most significant barrier is the perception around cost. Many assume that complex machinery invariably leads to expensive products. However, this assumption focuses on unit price, not total project cost.”

The data centre sector is perhaps the sector most ready for adoption. These projects require thousands of similar structural elements – foundations, pile caps and cable management systems – but each must be customised to varying sizes, site conditions and soil types. With major operators such as Google, Facebook and Apple continuing to experience rapid market growth, traditional methods of construction simply cannot deliver what is needed at the required speed. These players are also keen to reduce construction-related (embodied) carbon emissions to offset their operational carbon. Additive manufacturing technology can significantly reduce CO₂ from the construction phase and accelerate delivery timelines.

Looking to the future

Mass adoption of 3D printing requires extensive industry education and partnership building. We’re engaging engineers, contractors, regulators and clients through workshops and pilot projects. Meanwhile, working with bodies such as the National Grid creates powerful case studies that demonstrate benefits and encourage broader adoption across sectors.

The scalability of our asset-light technology means we can rapidly add production capacity for large projects. As we move from single foundations to projects requiring hundreds or thousands of units, the advantages become increasingly compelling.

The construction industry has always been cautious – rightly so given the critical importance of structural safety. However, the evidence is clear: 3D printing can deliver stronger, more sustainable, cost-effective solutions while integrating seamlessly into existing workflows. The question now revolves around how we can scale adoption to meet the infrastructure challenges which lie ahead.

Keep up to date with DC+: sign up for the midweek newsletter.