Digital Team of the Year shortlist 2026

Teams from eight businesses have made the shortlist for Digital Team of the Year at the Digital Construction Awards 2026.

This category, sponsored by nima, recognises the team driving digital transformation and/or information management best practice within their business. It could be a team working on the design, construction, operation or maintenance of a built asset, or a team driving digital transformation within their organisation.

Here are the eight teams that made the shortlist.

AtkinsRéalis | Digital R&D unit

The new digital R&D team at AtkinsRéalis was formed six months ago through a first-of-a-kind, 24-hour hackathon recruitment process.

The team has a diverse skills base around data science, AI, gaming engines and immersive technologies. It has rapidly established strong governance and agile delivery structures, adopted Scrum, Kanban boards and collaborative tools like Miro.

The team quickly identified an opportunity to enhance its existing virtual site access by building a smarter training platform based on 360° site data. This resulted in a gamified, immersive training platform called Hazard Quest.

Delivery required overcoming substantial technical challenges, such as building a cost-efficient pipeline for generating photorealistic 3D environments from short 360° videos using a novel AI technique, as well as integrating these 3D environments into a gamified training platform.

The team developed a prototype focused on safety-critical training, allowing them to test core assumptions and build the technical backbone. By month three, the team had produced two prototypes exploring the impact of gamification and photorealism on learning. They conducted A/B testing with 20 new joiners, demonstrating that an interactive 3D induction experience significantly improved retention of key safety information, such as the location of first-aid kits and fire exits.

Part of the team’s strategy for developing an innovative product was a social media campaign on AtkinsRéalis’s intranet. This received more than 4,200 impressions and 18 creative submissions that further informed development.

During the early stages of the project, the team held collaborative workshops with stakeholders to address initial scope misalignments and ensure a shared understanding of objectives. User research combined quantitative testing with one-to-one focus sessions, which revealed that photorealistic environments improved spatial awareness by 20%.

Despite challenges such as IT delays and being early-career professionals, the cohort transformed from a newly formed group into a highly effective, agile team capable of rapid experimentation and disciplined delivery.

By developing a new solution in just six months, they demonstrated the value of a diverse, cross-functional R&D team and a sprint approach to service development in the engineering consultancy sector.

A conservative estimate suggests that deploying Hazard Quest could avoid 10.8 tonnes of CO2 annually and save £45,000 per site, as well as reducing the number and cost of safety incidents.

Balfour Beatty | Copilot transformation team

Balfour Beatty set out to harness AI, empowering innovation, better decision-making and competition by committing to a £7.2m investment in Microsoft Copilot – one of the largest AI investments in UK construction.

In March 2025, Balfour Beatty formed the Copilot transformation team to design and deliver an AI transformation programme for its 13,000-strong UK workforce. The company needed to build confidence among employees with varying digital skills, address concerns about AI’s impact on jobs, and maintain robust data protection and compliance.

To achieve this, the team completed a rigorous technical readiness assessment and prepared more than 13,000 laptops for Copilot use, completed a data privacy impact assessment, and updated policies on generative AI and IT acceptable use. Network and infrastructure performance were baselined and monitored ahead of go-live, with detailed cutover and rollback plans.

The executive committee was coached through the investment decision and each member was paired with a former apprentice for one-to-one Copilot learning. This ensured leaders understood the tool’s potential and modelled digital adoption.

Among the team’s achievements were:

- mobilisation of a Copilot leader community of 50 and a champion network of 490;

- the training of IT, Copilot leaders and the programme team, creating a pool of 350 support experts;

- delivering sequential core training series for all employees, and tailored learning for early adopters and senior leaders via webinars, in-person sessions and self-help resources;

- running multi-channel communications, including social media, CEO blogs, FAQs, myth busters, a dedicated Copilot Hub and more; and

- launching 33 in-person sessions with 320 attendees in-person and a further 760 online.

In just 12 weeks, the project delivered 46 training sessions reaching 6,345 users, with an average attendee feedback score of 4.5 out of 5. Adoption exceeded the 50% engagement target with 6,354 people using Copilot at least once since launch. This translates to 336,237 Copilot actions taken, assisting 31,248 hours of tasks. Document accuracy improved and duplication was reduced. Early results show faster decision-making and streamlined workflows, including a 5% quality improvement on a £100m contract.

Balfour Beatty Vinci | HS2 Area North BIM team IFC processing

As the main works civil contractor for HS2 Area North, Balfour Beatty Vinci’s (BBV) BIM team plays a critical role in delivering structured, high-quality openBIM data to the employer. A key focus of its work is ensuring all 3D model information is correctly categorised and organised to support efficient data consumption in the operation and maintenance phase.

BBV’s challenge was to deliver several thousand digital infrastructure assets as IFC4.3. These assets were varied, complex and housed in secure environments requiring offline validation and strict data governance. As IFC4.3 was newly released, industry support from common software was still developing. BBV set targets to meet this challenge in-house and leave a positive legacy.

The team’s approach prioritised an autonomous and scalable process to normalise outputs from source applications, implement data standards, evidence compliance against a suite of Information Delivery Specifications (IDS), and comply with buildingSMART validation.

There were numerous key challenges, including learning the IFC schema and IDS definition, correcting non-compliant IFCs from sources, minimising CAD licensing costs and having limited IFC editing capabilities. The team also needed to find a way to process large IFC files, integrate complex CDE systems and improve processing outcomes.

BBV created AI-developed Python scripts to build an automated pipeline, using Microsoft Fabric, to industrialise IFC normalisation and validation.

The process progressed non-compliant IFC2x3 models to fully assured IFC4.3 outputs to meet the appointing party Exchange Information Requirements. BBV developed a custom-built IFC application (Viper) to manually edit any IFC outputs that could not be processed automatically.

Initially, Fabric’s limited memory caused time-outs when processing large IFC files. To overcome this, BVV re-engineered its scripts to process files in segments, clear memory between operations, and complete entity mapping without crashing.

BVV tackled the challenge of reading and modifying IFC and IDS files from Azure Blob Storage. After extensive trial and error, BBV code successfully enabled communication between Fabric and Azure, allowing seamless file handling.

Dashboarding solutions were introduced to improve transparency, script execution times, success and failure rates, and overall workflow health.

Outcomes have been transformative. Validation and classification tasks now take minutes instead of hours. Offline validation and cryptographic access control ensure full compliance with data protection policies. Reliance on expensive commercial tools and supply chain resource requirements has been eliminated. Data quality has improved through early detection of non-compliant files, as well as sustainability through reduced cloud dependency. Dashboarding has improved monitoring and accountability.

Bowmer + Kirkland | Digital construction team

Bowmer + Kirkland’s (B+K) four-person digital construction team was first established in 2016, but as the business expanded, it struggled to support more than 85 projects. The team was expanded from four to 12, with improved regional representation, project support and collaboration.

B+K delivered more than 2,000 hours of targeted training and established dedicated knowledge-sharing channels to provide ongoing, consistent support across the team in areas such as information management, the Viewpoint for Projects CDE, COBie and Morta.

A key piece of training was the buildingSMART foundation course, with certification achieved in October 2025. Working with its supply chain to improve overall project delivery, the B+K team ran in-person sessions with more than 100 attendees to better understand challenges and opportunities. The team worked to foster closer communication with technical advisers, including Mace, AtkinsRéalis and Arcadis.

An overarching aim was to streamline project reporting and compliance and reduce the time taken to produce reports by half. To help achieve this, the team developed the B+K DigitALL Compliance Tool, an in-house project information management tool. This is a free tool created in Solibri for supply chain partners to help them better understand project requirements and use accurate model data to track performance and carry out analytics.

The team piloted the tool across 10 projects and then refined it using feedback before the final version was rolled out across 42 projects, covering RIBA Stages 3 to 6. Addressing inconsistent data standards, the team produced a one-page guide and training video for supply chain partners.

Key outcomes included:

- reduced project reviews from an average of 15 per stage to two or three, resulting in faster sign-off and improved efficiency and outcomes;

- information management review time was cut from 16 to one hour per building report, almost a 94% improvement, far exceeding the initial target of 50%;

- improved relationships with technical advisers and clients;

- precise monitoring of supply chain progress and technician performance;

- standardised methodologies across regions and supply chains; and

- a collaborative environment, promoting honest and open feedback, and positive mental health and wellbeing for the team and supply chain.

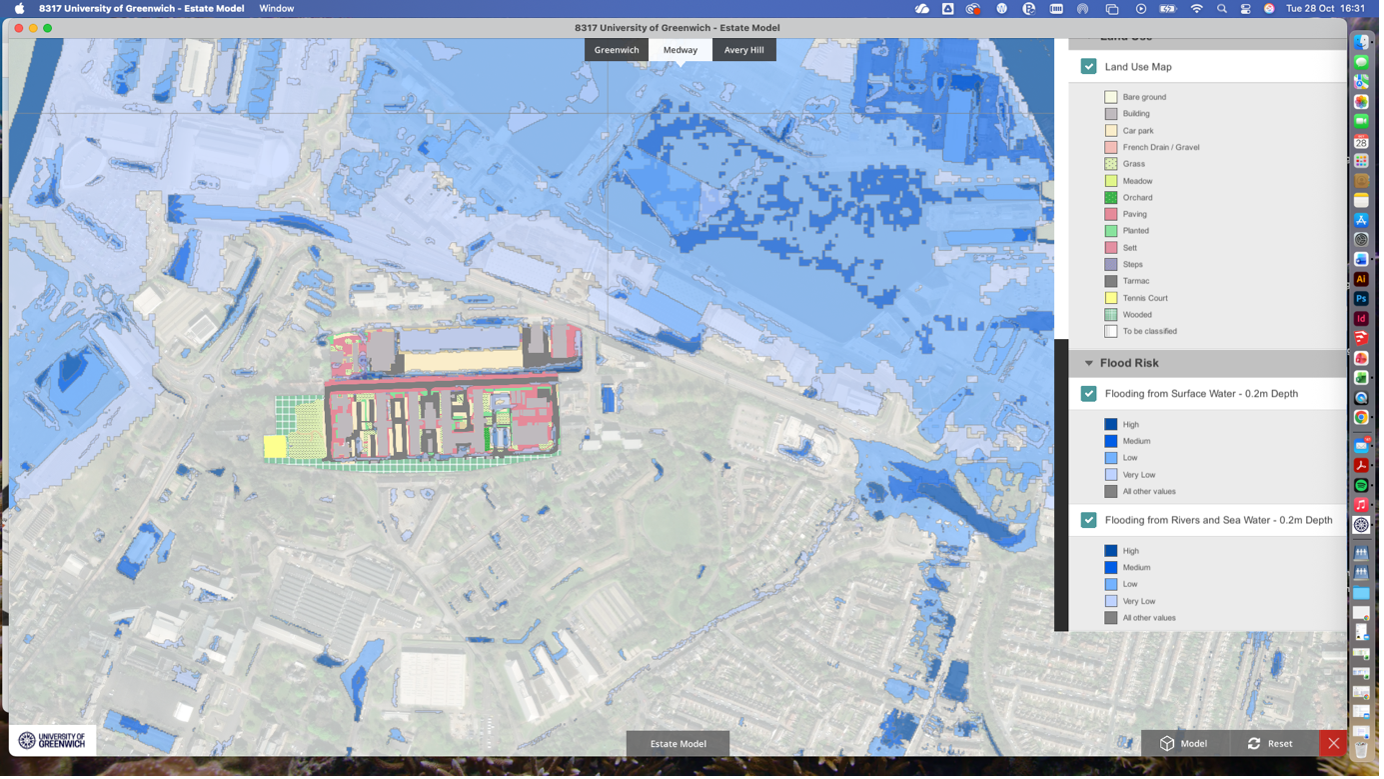

Heathrow Airport | Digital asset delivery

Heathrow is one of the world’s most complex infrastructure environments. It has a £4.5bn portfolio, including 450 projects, and 412 project managers, along with thousands of staff from delivery partners.

Capital projects delivery has faced significant risks due to fragmented and poor-quality asset data, causing delays, cost overruns and inefficiencies. Implementing changes was further complicated by the need to operate within Heathrow’s live environment, where disruptions could affect millions of passengers.

Additionally, all digital upgrades require full cyber-safety approval before implementation. Siloed project work, unclear information needs and use of unmanaged tools meant there was no single source of truth, risking data duplication and loss of value.

To address this, the Heathrow team developed a four-phase approach: Discover, Design, Build and Deploy. In the Discover phase, the team engaged across the organisation and with the supply chain. They gathered more than 150 user stories to identify major challenges.

During the Design phase, a small expert team grouped these stories into process, organisation and people, technology and information, and created a roadmap to strengthen foundations for data-driven decisions.

The Build phase updated standards and contracts to industry best practice and ISO 19650. A CDE was implemented across Heathrow SharePoint, Autodesk Construction Cloud and M-Files. Templates and centralised dashboards were introduced, and health and safety design risks were managed according to 19650‐6. Automated asset assurance processes were established, while the team explored AI use for document search and standards mapping.

The Deploy phase rolled out pilots across key projects. Feedback from these was used to create minimum viable products for wider adoption. These initiatives improved progress tracking through systematic reporting and digital workflows, with change management guided by the Prosci ADKAR model with super-users, tailored training and stakeholder engagement.

Behavioural resistance was addressed through simplified messaging and benefits‐led demonstrations.

Around 90 projects have adopted the new approach with a total of £6.7m in productivity benefits, achieving a return of £2.10 for every £1 invested. Project managers save around one hour daily on locating information, while 85% of high-level health and safety design risks have been reduced to medium or low.

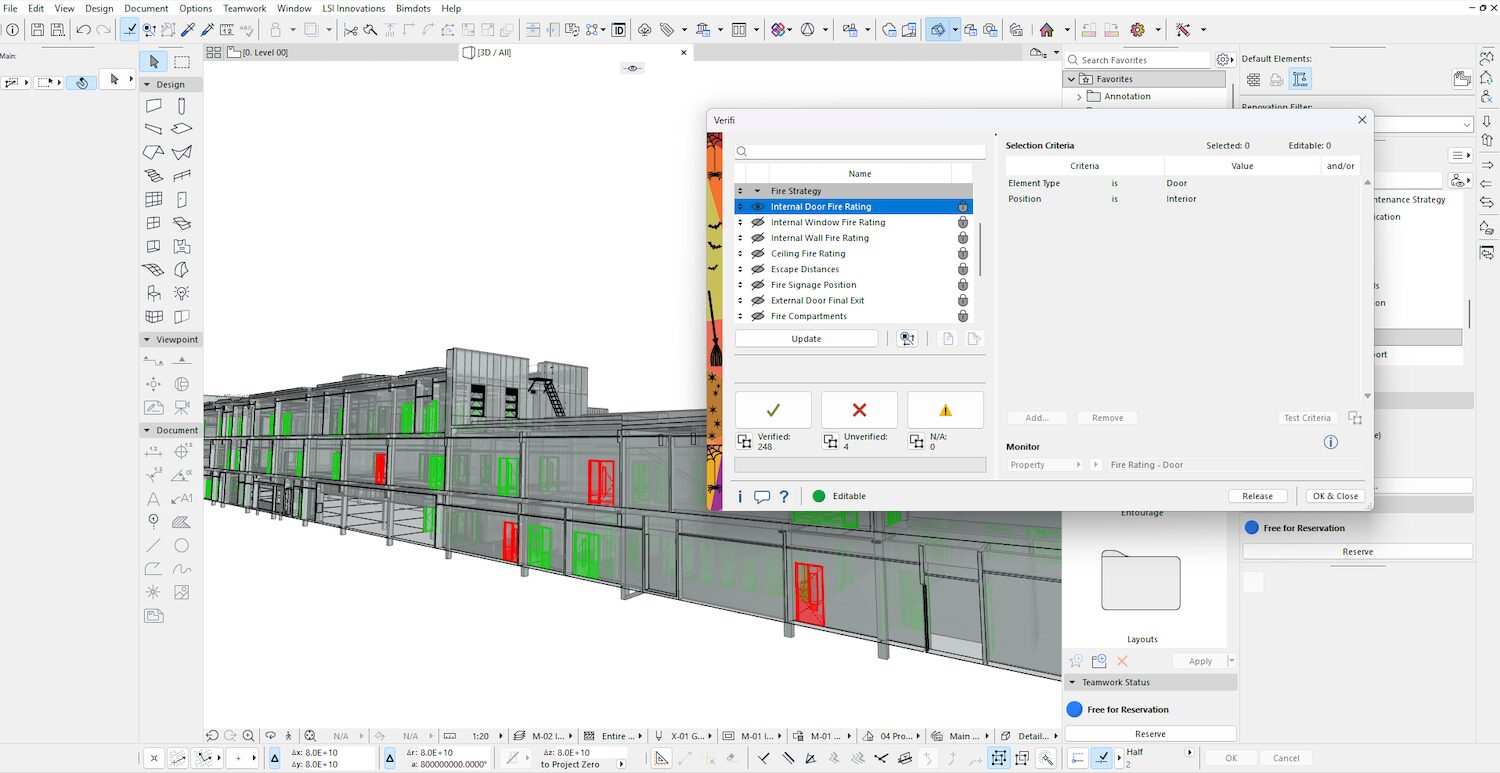

LSI Architects | Digital technology team

LSI Architects’ digital technology team has been exploring how AI can be integrated into workflows. While AI assistants within CAD software will become increasingly capable of manipulating geometry and data, LSI recognises that robust verification systems are essential to maintaining high-quality outputs.

Existing QA processes, operating under 9001 Quality Management standards, rely on manual checks within Archicad in combination with external tools such as Solibri and Excel. While adequate, these established workflows are manual, convoluted and prone to error, particularly when working with large datasets.

Design development changes could also fall through QA gaps undetected and existing methods lack audit trails to monitor changes to verified elements. These all create barriers to efficient AI adoption within CAD systems.

Thus, the digital technology team developed an AI verification system featuring ‘verification sets’, which define filtering criteria. The verification tool checks that the AI agents have correctly updated specific building elements, such as adding fire ratings to walls. It flags different elements to show verification status, and records who verified each item and when. If these verified elements are later changed, the tool automatically flags them for rechecking.

The system mitigates AI hallucinations and supports teams’ upskilling.

Challenges included the niche nature of the Archicad API, teamworking reservation requirements and initial data storage limitations. These were addressed through automatic reservation solutions, a rewrite of the data storage methodology to support near-limitless data formats, and systematic performance testing to minimise slowdowns. The tool has also been futureproofed to support seamless upgrades.

The verification tool establishes a pathway to check models against project standards (such as building regulations), positioning it as a comprehensive compliance platform.

Early feedback suggests significant efficiency gains, with manual room elevation checks reduced from 15 minutes to just five minutes per room, saving hours per project.

Mott MacDonald | Information management team

Mott MacDonald’s information management (IFM) team is 35-strong and spans engineering, computer science, mathematics and urban planning with diverse nationalities and experience levels.

The IFM works closely with internal teams and clients, including contractors and owner-operators, to implement digital tools, data systems and processes. It provides robust frameworks for information governance and model management, and introduced standardisation and automation that have improved task efficiency by 20-50%.

Training and upskilling are central. Last year, the team shared tools, processes and training with hubs in Europe, the Americas and the Middle East, contributing to the Standard Project Delivery Model initiative. This year, it has launched a digital upskilling programme for more than 300 colleagues, including ‘Future of Engineering’ events and an AI and coding club.

The IFM team has a collaborative culture through weekly knowledge-sharing sessions and quarterly strategy away days. It is trying to address challenges, such as new technologies, regulatory changes and skills shortages, by developing innovative solutions such as the Moata Safe by Design tool, automating onboarding processes and designing standard data models for global project delivery.

The IFM team has delivered measurable results. On HS2 Phase 1, BIM services saved 85,000 modelling hours and £4.1m. Its asset information tool accelerated carbon assessments, enabling instant reporting and supporting socially responsible optioneering. On East West Rail, automated onboarding reduced mobilisation time by 60%. At The Line smart city in Neom, Saudi Arabia, deliverables tracking halved coordination and reporting effort. For the Ontario Line subway in Toronto, a CDE was established for 70 organisations, earning a Bentley Systems award.

The team also delivers yearly university lectures to built environment students at Reading University, supports Mott MacDonald’s Inspiring Engineers scheme, mentors sixth-form students and supports apprentices.

SSEN Transmission | Accelerated Strategic Transmission Investment digital team

Efforts for preparing full-scale project delivery for this SSEN Transmission project ran from January 2025 to the present. The challenge was twofold: roll out a new CDE, while delivering a live, standardised high-voltage direct current converter (HVDC) station design across multiple sites.

This is the first UK-wide standardised converter station design, developed in two variants: coastal (with indoor equipment) and inland. As a client, SSEN holds a unique integration role between the standardised design partners and the wider supply chain. High data accuracy, reliable processes and close collaboration between engineering teams and design partners were essential.

CDE adoption had just begun, yet project delivery and training for internal teams and contractors had to start immediately. This was a technical and business-critical transformation, combining digital strategy, training, governance and engineering.

A specialist digital information team worked alongside project information officers, BIM, engineering leads and contractors to make the new CDE functional and embed best practice. The team became CDE gatekeepers, drawing on previous project lessons learned to develop improved workflows, governance and practical workarounds.

A holistic training programme was rolled out to internal teams and contractors, covering system navigation, 19650 standards, compliance, structured data, and quality and assurance responsibilities. A hybrid approach advanced previous “pseudo-BIM” approaches into true digital information management strategy, balancing live design with contractor-led delivery.

The CDE was integrated with other tools and workflows, making reporting easier and ensuring asset data would be handed over efficiently for long-term use. Governance was aligned with 19650 and corporate standards.

A centralised, site-adaptable modelling system was used across four HVDC (high-voltage direct current) sites using Autodesk Construction Cloud and Navisworks Manage, with master coastal and inland models replicated per site. A structured clash process, geolocation control and robust governance ensured standards, spatial integrity and efficient design coordination and information flows.

Cultural and capability shifts moved teams from 2D/document-heavy habits to BIM-enabled workflows, improving collaboration. Digital rehearsals and structured reviews reduced coordination defects and strengthened health and safety planning. Standardised digital processes supported the 45% carbon reduction ambition, and unlocked efficiencies in procurement, design and delivery.

Celebrate with the best

The winner will be revealed at the gala dinner at the London Marriott Grosvenor Square on 18 March. You can join the shortlisted entrants by booking your seats at the awards. There is an early bird discount for those who book tables by close of play 23 January.

The Digital Construction Awards are organised by Digital Construction Week, DC+, Construction Management and the Chartered Institute of Building. Bluebeam, nima and Sage are among the sponsors.

To find out more about the awards, head to digitalconstructionawards.co.uk.

To become an awards sponsor, email Karolina Orecchini.

Keep up to date with DC+: sign up for the midweek newsletter.