Digital Construction Project of the Year 2026 shortlist

Five schemes have made the shortlist for the Digital Construction Project of the Year at the Digital Construction Awards 2026.

This category celebrates what can be achieved through the successful implementation and adoption of digital processes and technologies on a project (either a new build project or a maintenance, retrofit and refurb project). This can apply to a specific issue, challenge or package on a project, or the entire project.

Here are the five shortlisted projects.

Brook Mead Academy | LSI Architects/Wates Construction

LSI Architects led the design and architecture for Brook Mead Academy, delivering two new net-zero carbon in operation school buildings to accommodate 1,200 pupils. The project is part of the Department for Education’s (DfE) Construction Framework 21 programme, replacing temporary facilities and providing critical educational spaces in a deprived area, adhering to the DfE’s stringent employer’s requirements and output specification.

This project marked LSI’s first experience of the DfE’s updated and rigorous COBie standards, and thus the team had to establish new processes to deliver data-rich models to demanding timescales. This meant that 24,000 data properties needed to be manually checked and verified for completeness and accuracy before being exported as IFC and COBie files. This was an extremely time-consuming and labour-intensive process undertaken by LSI’s technical teams.

Existing QA processes relied on manual checks, schedules, properties and graphical overrides within LSI’s principal CAD software, Archicad, in combination with external tools such as Solibri and Excel. While adequate, these established workflows were prone to error, particularly when working with large datasets – natural design development could fall through quality assurance gaps undetected.

LSI also found multiple locations in which to add a single piece of data that made mapping to the correct location a significant challenge.

To overcome this, the firm introduced presets within the model to define, as much as possible, enforced locations to add data and built translators to export it correctly as an IFC file.

Alongside this, LSI also developed a full suite of Solibri classification and rule sets to facilitate automated compliance against the DfE standards on its IFC exports.

LSI’s BIM manager worked closely with the project team to ensure data was in the right place, in the right format and at the right time. The COBie export, containing all the data required, was then created using Solibri.

The firm submitted both IFC and COBie files in advance for stringent checks and secured exceptional pre-submission scores of 100% and 99.89% compliance for its two buildings – setting an industry-leading standard.

The project has become a benchmark for LSI’s internal QA practices, allowing it to introduce automated model checks on all its projects, improving both efficiency and accuracy.

As a direct result of this experience, LSI’s digital technology team has also developed an AI-ready verification tool, which complements LSI’s internal QA processes under ISO 9001 by providing a platform to verify, record and track compliance.

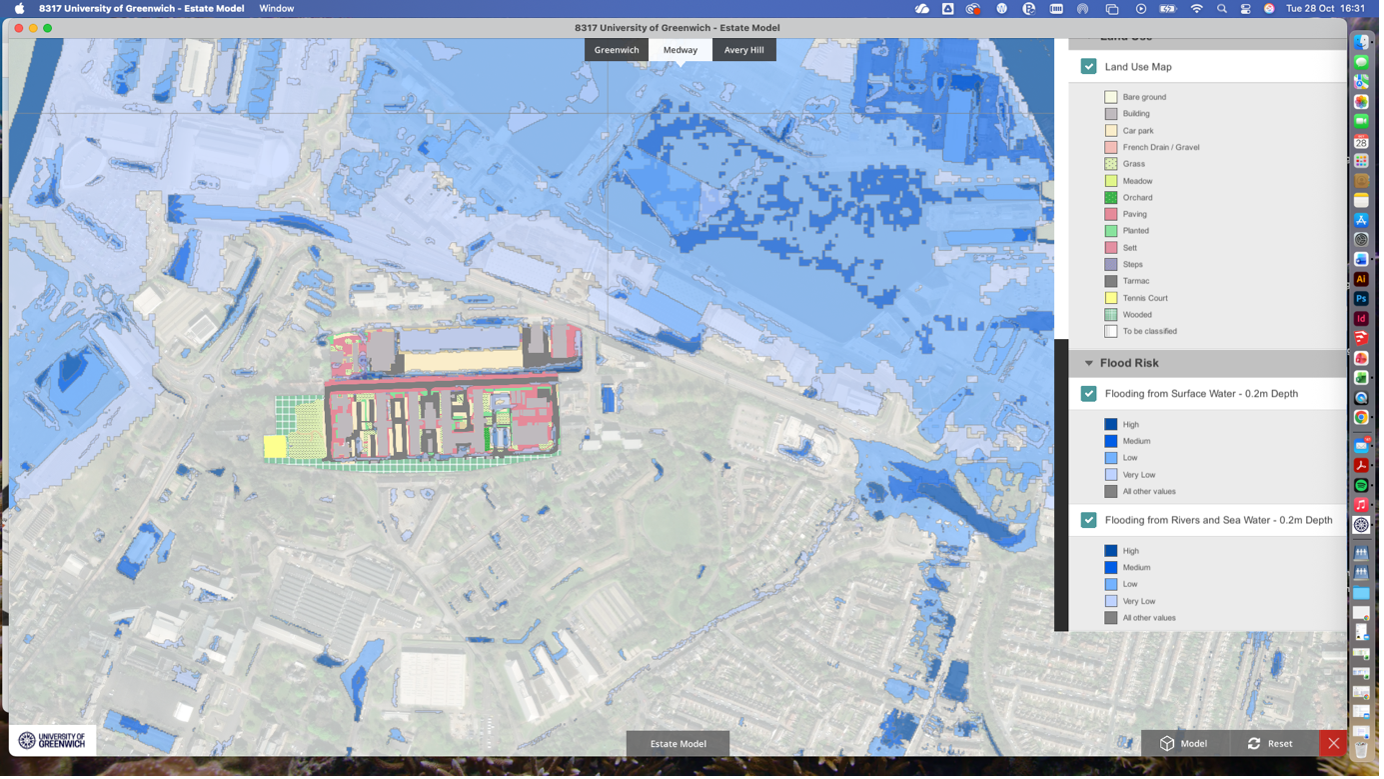

Meridian Water | Taylor Woodrow

Taylor Woodrow, as part of the Meridian Water regeneration project led by Enfield Council, is delivering strategic infrastructure to support 10,000 homes and 6,000 jobs. The scope includes roads, bridges, parks and sustainable drainage systems. The engineering team at Taywood Engineering was tasked with using digital tools to enhance project efficiency, collaboration and sustainability across four concurrent work packages: earthworks, highways, utilities and structures.

Key challenges included managing complex interfaces between packages, ensuring timely access to accurate data, and meeting the client’s request for GIS-based asset handover. Traditional planning methods lacked the granularity needed for effective short-term decision-making, while existing 4D tools did not adequately visualise interdependencies. Additionally, complying with 19650 standards for information management was labour-intensive and error-prone when done manually.

A major breakthrough was the creation of a detailed 4D model integrating subcontractor schedules, drone-generated surface models and design data. Unlike traditional 4D tools that only show high-level tasks, this model visualised granular activities such as “fix rebar → build formwork → pour concrete”, enabling the site team to understand spatial and temporal interfaces across the works packages. This helped mitigate planning risks and improved communication. To overcome hardware limitations, the team developed a web-based control project allowing access to the model on low-spec laptops.

Using the Alteia visual intelligence platform, the team conducted regular drone surveys to generate high-resolution aerial imagery and 3D photogrammetry models. These tools enabled real-time site monitoring, stockpile assessments and progress tracking without relying on complex CAD software. This streamlined data collection, reduced manual labour and empowered site teams to make informed decisions quickly.

To ensure adherence to BIM execution standards, Taywood Engineering developed an automated Aconex workflow that validated documents against 20 project information rules. It audited TIDPs (Task Information Delivery Plans), identified duplicates and mismatches, and generated a compliant MIDP (Master Information Delivery Plan). This automation replaced manual checks, saving time, improving accuracy and enhancing data quality across the project.

Responding to the client’s request for GIS-format asset data, Taywood Engineering collaborated to refine the legacy schema and developed a semi-automated workflow that converted CAD geometry and metadata into GIS formats, applied custom schemas and produced scalable, accurate asset registers. The outputs supported dashboards and web maps, improving long-term asset management and decision-making.

One Broadgate | Sir Robert McAlpine/British Land/Focchi/Morrisroe

One Broadgate is a 500,000 sq ft, mixed-use, 14-storey development adjacent to Liverpool Street station, delivered ahead of schedule and within budget for British Land in July 2025. The project tackled complex challenges, including integrating advanced building systems, managing a congested site and meeting the client’s demanding requirements for flexibility, operational efficiency and futureproofing. Key client targets included BREEAM Outstanding, WELL Platinum, NABERS 5-star, and circular economy integration.

Sir Robert McAlpine adopted a digital-first strategy, collaboratively developing the Employer’s Information Requirements with the client to ensure structured data and asset traceability. The contractor’s project-based, dedicated digital construction team drove adoption and training, and promoted innovation, including research technology trial partnerships with University College London (UCL). Digital tools enabled proactive risk management, transparent progress tracking and seamless stakeholder coordination, with early engagement and data sharing across the supply chain proving vital.

The team overcame challenges such as integrating new and legacy platforms, ensuring data consistency in delivering on British Land’s bespoke asset schema for future FM and smart building use, and creating a bespoke materials passport process. Furthermore:

- the integration of advanced digital tools required a shift in mindset and workflows for many partners;

- developing the bespoke material passport solution was complex, involving linking components to EPDs, manufacturing origins and embodied carbon values using Revit, Grasshopper, Python scripting and Madaster; and

- the adoption of new immersive technology trials (eg, AR headsets) presented initial challenges in aligning digital and physical works, but these were overcome through collaboration with UCL and iterative trials.

Early challenges included ensuring consistent data capture and overcoming resistance to new digital processes. These were addressed through targeted training, structured onboarding, and demonstrating the tangible benefits of digital adoption. The team also adapted by fostering a culture of continuous improvement, learning from each phase and refining processes to ensure project goals were met.

Outcomes included improved delivery certainty, enhanced client satisfaction and industry-leading productivity with the project being identified as a case study in the 2025 Construction Productivity Taskforce report, highlighting examples from data collected from cladding installation and in-situ frame.

Furthermore, the project secured a BREEAM innovation credit, reused 27% of demolished materials, and delivered a replicable digital delivery methodology, establishing One Broadgate as a benchmark and future blueprint for digital construction delivery within Sir Robert McAlpine.

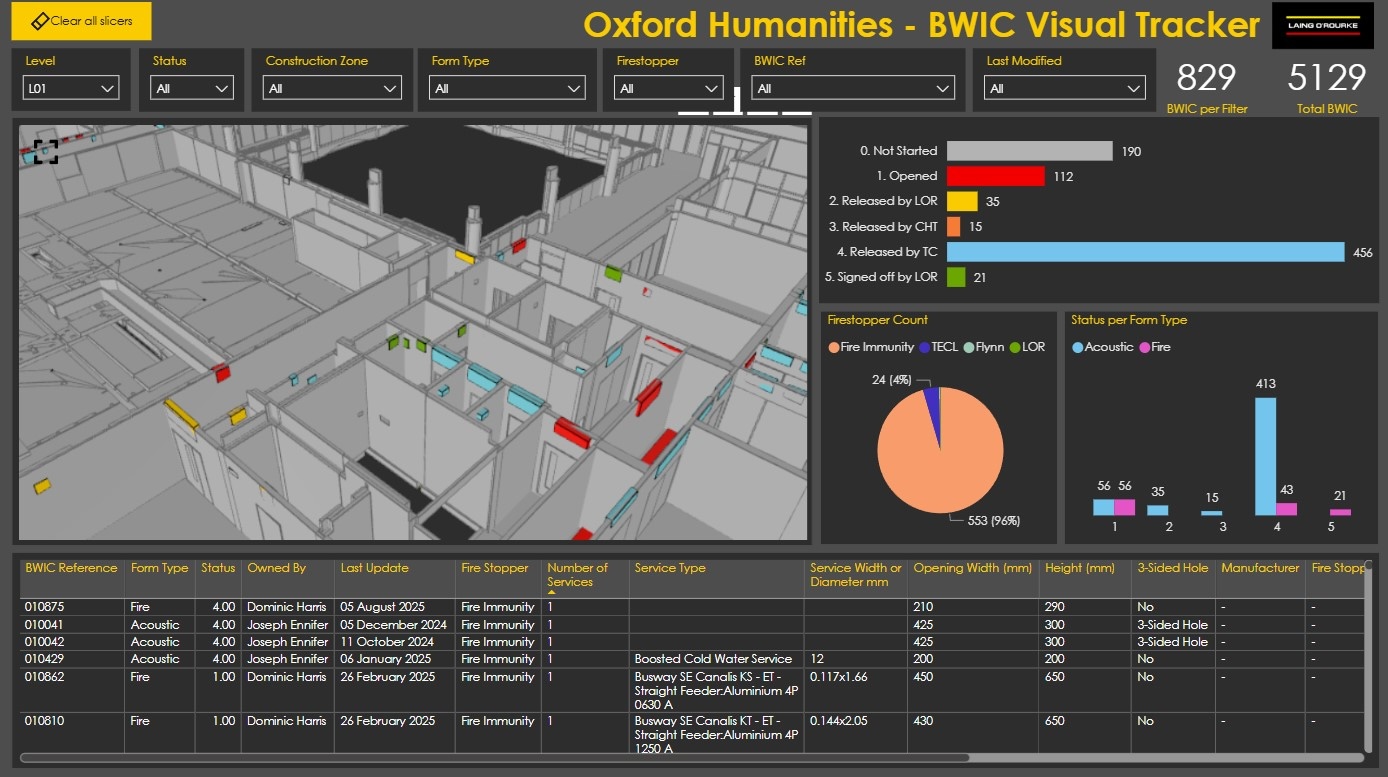

The Stephen A. Schwarzman Centre for the Humanities – Oxford University | Laing O’Rourke

The Stephen A. Schwarzman Centre for the Humanities is a transformative project for the University of Oxford and the city of Oxford itself. As the university’s largest capital development to date, the centre now houses multiple humanities faculties under one roof for the first time, creating new opportunities for interdisciplinary collaboration. With theatres, cinemas and exhibition spaces, accessible to the public, the building reinforces Oxford’s role as a cultural hub.

A key technical challenge involved the management of more than 5,000 Builders Works in Connection (BWIC) penetrations through fire-rated and acoustic floor and walls. These penetrations, for MEP services, had to comply with rigorous fire safety and structural standards.

Traditional verification methods for BWICs are manual, time-consuming and prone to error, posing risks to programme delivery and budget. The lack of a unified digital process means that coordination between design, onsite execution and compliance can be fragmented. This increases the likelihood of rework, delays and non-compliance, particularly in areas requiring fire-stopping and acoustic integrity.

The challenge was further compounded by the need to ensure that what was physically built on site had to be represented in the digital model, requiring precise coordination between multiple stakeholders, including MEP designers, fire-stopping specialists and suppliers.

To address these challenges, Laing O’Rourke implemented a digital-first strategy that transformed BWIC verification into a streamlined, automated process. The solution integrated existing software tools such as Solibri, Power BI, Trimble Connect AR and Field View to create a new structured workflow that linked 3D BIM data with onsite inspections and handovers. This digital thread enabled real-time monitoring and decision-making, risk mitigation and quality assurance throughout the project lifecycle.

Penetration checks, which previously took several weeks to complete, were reduced to just a single day. This dramatic improvement saved more than 600 hours across the project lifecycle, eliminated the need for external consultants, and helped avoid costly rework. These efficiencies played a crucial role in maintaining the project timeline and mitigating overall delivery risk.

The methodology proved scalable and adaptable, making it suitable for replication across other projects with similar compliance requirements. Classification systems and dashboard templates have been reused with minimal modification, supporting wider adoption across Laing O’Rourke’s portfolio. Lessons learned from this project have been shared across the wider business and have helped shape internal standards.

University of Birmingham – Molecular Sciences Building | University of Birmingham/Morgan Sindall Construction/BakerHicks

University of Birmingham’s Molecular Sciences Building spans 11,230 sq ft and comprises a mixture of specialist laboratory spaces, offices, tutorial space, collaborative spaces and a new two-storey energy centre.

The project required a verified digital twin whereby each modelled element’s position would need to be validated against the final construction to within a 50mm tolerance. The location of objects had to be validated throughout the entire construction process, not just at the end.

Asset management challenged Morgan Sindall to ensure not only the fidelity of the modelled geometry, but also the asset data for specialist systems and equipment. The university has its own asset data classification system and specific parameters that were tied to its FM and campus-wide operations.

The contractor was also required to regularly demonstrate to the university estates team how it would validate the models and data outputs during various information exchange milestones.

To meet the validation requirements, Morgan Sindall needed a suitable 3D output to compare the site installation against the design models to create the digital twin. To meet the laser scanning specifications, Morgan Sindall invested in high-spec Leica scanners that could create point clouds of the density needed to demonstrate the 50mm tolerance deviations.

Third-party consultant Naska converted the point cloud data into a 3D model that could be compared with the designers’ models using AI and create a compliance tolerance reporting heat map to verify if the build was within tolerance.

Revizto was used as the model management platform for issue management and clash detection. Models were hosted in the cloud so that the contractor had access to a live federated model and semi-automated clash detection. This was vital for design management and to coordinate the consultant’s intent with the build on site.

Oculo AI 360-degree photogrammetry was used daily by site staff to record and document site progress.

Ultimately, Morgan Sindall completed the comprehensive asset dataset as required, aligned to 576 NRM codes and more than 73 bespoke university parameters. All compiled data was ready for integration with the university’s FM system. Morgan Sindall now uses this project as an exemplar of how to deliver complex projects with challenging BIM deliverables.

Celebrate with the best

The winner will be revealed at the gala dinner at the London Marriott Grosvenor Square on 18 March. You can join the shortlisted entrants by booking your seats at the awards. There is an early bird discount for those who book tables by close of play on 23 January.

The Digital Construction Awards are organised by Digital Construction Week, DC+, Construction Management and the Chartered Institute of Building. Bluebeam, nima and Sage are among the sponsors.

To find out more about the awards, head to digitalconstructionawards.co.uk.

To become an awards sponsor, email Karolina Orecchini.

Keep up to date with DC+: sign up for the midweek newsletter.