Design Innovation shortlist 2026

Laing O’Rourke and Arup are among those shortlisted for the Design Innovation category at the Digital Construction Awards 2026.

This category recognises the best use of digital technology and data to enhance the practical aspects of building and project design for successful delivery. This category is not focused on design aesthetics.

Here are the four entries that made the shortlist.

BIMcollab/Laing O’Rourke

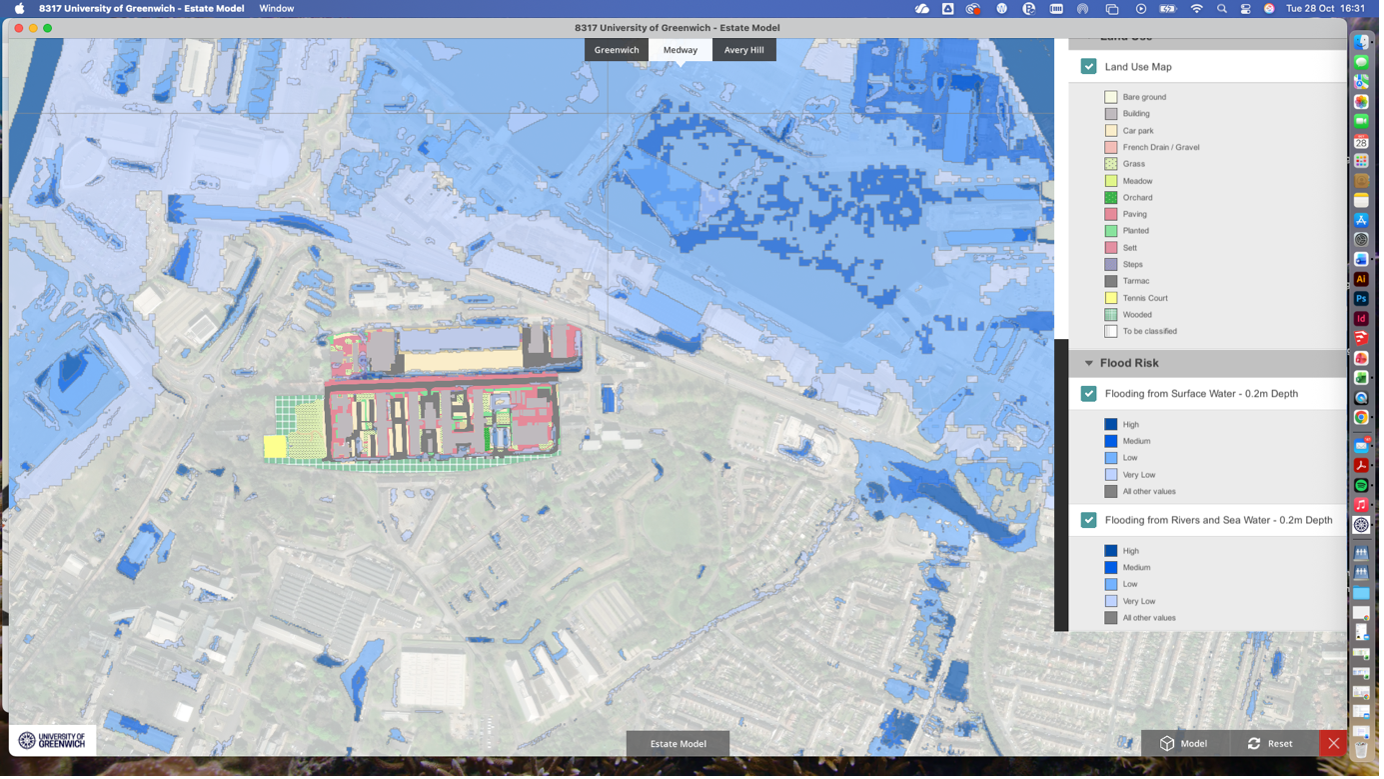

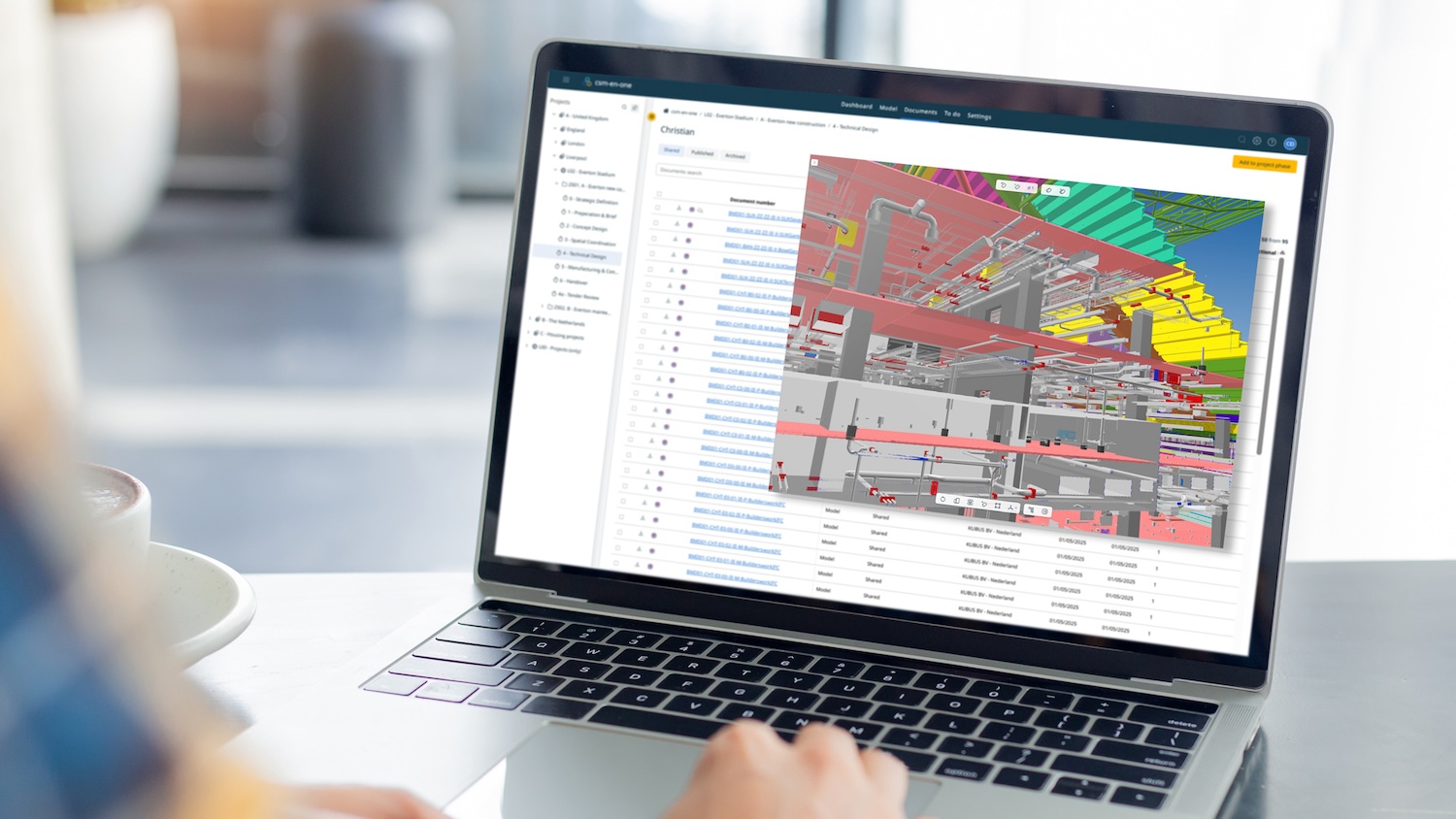

Laing O’Rourke’s internal design teams faced the challenge of coordinating design projects across different organisations and disciplines. To overcome this, the contractor deployed the BIMcollab platform to deliver an enterprise-wide upgrade of design coordination and issue management.

This initiative enabled multi-organisation teams to collaborate in a single, transparent digital environment. Building on learnings from previous projects, such as the Everton Stadium, and a decade-long partnership with BIMcollab, Laing O’Rourke standardised cloud-based coordination workflows and rolled out live dashboards, structured responsibilities and shared visibility of issues across consultants and subcontractors.

BIMcollab served as the collaboration platform, while Laing O’Rourke led adoption, training and governance. Email- and spreadsheet-led processes were replaced with a data-driven and auditable approach aligned to ISO 19650. This resulted in faster loops from issue identification to resolution, improved confidence in design status, and increased shared ownership of close-out.

The implementation delivered 100% visibility of design issues and actions for all contributors, reduced clashes and rework, and accelerated sign-off cycles, creating a scalable template for future programmes. This collaboration also demonstrated how a client-technology partnership can improve programme certainty and decision-making by uniting diverse organisations with a single source of truth.

Mynydd Isa Campus – delivering net-zero in operation school campus | Arup/IESVE

The Mynydd Isa Campus was commissioned to serve 1,300 pupils while achieving net-zero carbon in operation, a BREEAM ‘Excellent’ rating and 25‑year performance resilience to a +2°C future climate change scenario. Standard compliance modelling could not reliably predict long‑term energy use, unregulated loads or the effectiveness of natural/dual‑mode ventilation needed to avoid mechanical cooling. Uncertainty around occupant behaviour and build quality variations (airtightness, commissioning) threatened the ambitious carbon and comfort targets.

Arup’s building physics team selected the software platform IESVE for its dynamic, physics‑based simulation capability. IESVE enabled parametric testing of glazing, airtightness, natural/ventilation strategies, heating/cooling loads and integration of a 1,080‑panel rooftop PV system.

The platform modelled unregulated energy uses, future climate files and occupant behaviour sensitivity in a single environment. Conservative build quality scenarios were run, and close collaboration with the contractor refined on‑site targets for airtightness and system commissioning. Results guided the dual‑mode ventilation design, heat recovery and electrical control strategy.

The campus opened last year as Flintshire’s first net-zero carbon in operation school and achieved a BREEAM ‘Excellent’ rating. The rooftop PV installation generates more than 500,000kWh annually, exporting surplus energy during summer and reducing annual CO2 emissions by more than 100 tonnes.

The building operates without mechanical cooling, maintains thermal comfort under future climate conditions, and provides Flintshire County Council with lower operating costs, verified performance and a low‑carbon learning environment.

Precision at scale: applying custom technology for complex data centre coordination | Teecom

Large‑scale data centre projects face three persistent challenges: tight schedules that leave little margin for change; fragmented documentation that breeds errors; and escalating complexity that makes manual updates impractical.

When engineering firm Teecom is engaged late in the design cycle, engineers must revise dozens of racks, networking gear and security door hardware within days. However, traditional workflows rely on manual spreadsheets, isolated drawings and repeated red‑lining. This leads to duplicated effort, inconsistent records and heightened risk of costly delays.

Teecom addressed these challenges by building a bespoke suite of Revit‑integrated tools, including ACS Arrangements, Rack Builder and Connectivity Schedules, co-developed wth data science, ICT engineering and BIM experts.

The tools apply software development practices (automation, version control and testing) to the built environment workflow. Connectivity Schedule syncs an Excel database with Revit, providing end‑to‑end traceability of cabling and device connections; Rack Builder allows engineers to specify rack equipment in Excel and auto-populate Revit rack elevations; and ACS Arrangements automates placement of access‑control devices, merging Bluebeam mark-ups, Revit families and rule-based automation. All three maintain a single source of truth, eliminate manual re-entry and support rapid change management during RIBA Stage 4.

Across recent projects, the tools have delivered measurable gains. These include manual data entry cut by roughly 50% and time savings of 60% to 70%. In one case, updating more than 90 IT racks and reassigning IDs for around 5,000 network ports required only a few clicks, preserving an 80‑hour design window and keeping the Stage 4 deadline.

Unsurpassed clarity in hospital design | Laing O’Rourke

Hospital design projects have traditionally depended on 2D technical drawings, known as C-sheets, to detail fixture locations, equipment layouts and clinical workflow zones. NHS staff, both clinical and non-clinical, must validate and approve these layouts to ensure they meet stringent clinical functionality requirements, operational demands and regulatory standards.

However, these C-sheets are static drawings and inadequate for visualising true spatial relationships. Misinterpretations frequently cause late‑stage design changes, driving up costs and delaying programmes. Separately, transitioning from familiar 2D methods to immersive technology also raises practical challenges, such as the need for specialised CAD expertise and substantial computing power.

Laing O’Rourke partnered with VR specialist Immersive Interactive to create a collaborative suite that projects full-scale floorplan visualisations onto walls and floors and provides a VR model for 1:1 scale walk-throughs.

The platform integrates with existing issue‑management tools, allowing feedback to be captured directly alongside traditional C‑sheets. Automation utilities were built to streamline rendering pipelines, cutting manual effort and ensuring timely content delivery. When sensor tracking faltered, users could seamlessly switch to keyboard navigation, preserving session continuity.

The platform produced realistic visualisations that enabled clinicians and non‑clinical staff to identify functional gaps, safety hazards and equipment conflicts before construction, markedly reducing the risk of costly redesigns. The approach, now widely adopted within Laing O’Rourke’s healthcare portfolio, is expanding to other sectors where design complexity demands richer stakeholder input.

Celebrate with the best

The winner will be revealed at the gala dinner at the London Marriott Grosvenor Square on 18 March. You can join the shortlisted entrants by booking your seats at the awards.

The Digital Construction Awards are organised by Digital Construction Week, DC+, Construction Management and the Chartered Institute of Building. Bluebeam, nima and Sage are among the sponsors.

To find out more about the awards, head to digitalconstructionawards.co.uk.

To become an awards sponsor, email Karolina Orecchini.

Keep up to date with DC+: sign up for the midweek newsletter.